Top Solar Panel Clamps Manufacturer: High-Quality Clamping Solutions for Efficient Solar Installations

2026-01-06

As solar energy adoption accelerates globally, the reliability of every installation hinges on often-overlooked components—like the clamps that securely fasten panels. Choosing the right manufacturer isn't just about durability; it's about ensuring efficiency and safety from day one. At Topfence, we've pioneered clamping solutions that blend precision engineering with real-world resilience, setting a new benchmark in the industry. In this article, we'll explore what makes a top solar panel clamp manufacturer, why quality matters, and how innovations at Topfence can optimize your solar projects. Whether you're an installer, engineer, or sustainability advocate, discover the key to seamless, high-performance solar setups.

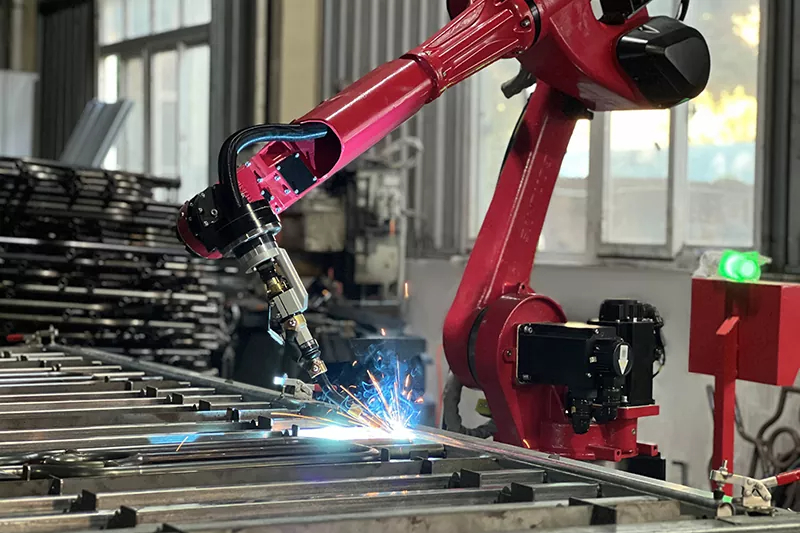

Innovative Clamping Technologies for Enhanced Solar Panel Durability

In the dynamic world of solar energy, clamping technologies have evolved beyond simple hardware to become critical components for ensuring solar panel longevity and performance. Innovations in this area focus on materials and designs that adapt to environmental stresses, such as wind, snow, and thermal expansion, without compromising panel integrity. By incorporating advanced alloys and flexible mechanisms, these clamps distribute pressure evenly and prevent micro-cracks that can degrade efficiency over time, making them an unsung hero in solar farm durability.

A standout approach involves smart clamping systems that use sensors and adjustable features to respond in real-time to changing conditions, reducing wear and tear on panels. Unlike traditional rigid mounts, these innovations allow for slight movements that absorb shocks and vibrations, thereby extending the operational life of solar installations by years. This adaptability not only safeguards the panels but also optimizes energy output by maintaining optimal alignment and reducing maintenance downtime.

Looking forward, the integration of lightweight composite materials and eco-friendly designs is setting new standards in clamping technology, offering enhanced corrosion resistance and easier installation. These advancements contribute significantly to the overall sustainability of solar projects, ensuring that panels remain secure and efficient throughout their lifespan, even in harsh climates.

Customized Clamp Designs to Fit Various Solar Installation Requirements

Solar installations often face unique challenges due to varying roof types, angles, and panel configurations, making standardized clamps ineffective. That's where custom clamp designs come in—engineered to address specific needs like thin-film modules, ballasted systems, or irregular mounting surfaces. By tailoring these components, installers can achieve a snug fit without compromising structural integrity, ensuring panels stay secure even under harsh weather conditions.

Instead of forcing a one-size-fits-all approach, customized clamps allow for creative solutions that optimize space and efficiency. For instance, adjustable brackets designed for metal seam roofs or lightweight polycarbonate clamps for carport structures demonstrate how personalization boosts compatibility. This flexibility reduces installation time and minimizes adjustments on-site, leading to smoother, more cost-effective projects.

Beyond functionality, these tailored designs also enhance aesthetics and durability, contributing to longer-lasting solar arrays. With innovations in materials and 3D modeling, companies can prototype clamps for unusual setups, such as floating solar farms or historical buildings. Embracing customization ensures that every installation meets both performance standards and specific client demands, setting a higher bar in the solar industry.

Durable Materials and Corrosion-Resistant Finishes for Long-Term Performance

Long-term performance is non-negotiable when it comes to high-demand applications, and the foundation of reliability lies in the materials and finishes chosen. Durable materials, such as stainless steel, aluminum alloys, and reinforced polymers, are selected not just for their strength but for their inherent resistance to wear, impact, and environmental stressors. These robust components undergo rigorous testing to ensure they withstand the rigors of daily use without compromising structural integrity over time. By prioritizing materials with proven longevity, we build products that remain dependable through years of service, reducing the need for frequent replacements and minimizing downtime in critical operations.

Corrosion-resistant finishes are essential for protecting surfaces from degradation caused by moisture, chemicals, or exposure to harsh climates. Advanced coatings, like powder coatings, anodization, and galvanization, create a barrier that shields the underlying material from rust, tarnish, and other forms of deterioration. This not only preserves the aesthetic appeal but also extends the functional life of the product by preventing weak points that could lead to failure. In industries ranging from marine to industrial manufacturing, these finishes are tailored to specific environmental challenges, ensuring that equipment maintains peak performance even in corrosive settings.

Together, the synergy between durable materials and corrosion-resistant finishes results in products that excel in longevity and reliability. This approach goes beyond basic specifications, focusing on real-world durability that translates to cost savings and enhanced user trust. By integrating these elements from the design phase, we create solutions that not only meet but exceed expectations for long-term performance, delivering value that endures through changing conditions and demanding applications.

Streamlined Installation Processes That Boost Efficiency on Solar Projects

Streamlined installation processes in solar projects are revolutionizing efficiency by cutting down on time and labor costs. By integrating advanced technologies like pre-assembled components and automated mounting systems, teams can handle complex installations with fewer errors and delays. This approach not only speeds up project completion but also allows for better resource allocation, making solar energy more accessible and cost-effective.

Adopting streamlined methods involves careful planning and coordination, ensuring that every step from site survey to final connection is optimized for smooth execution. This includes using detailed digital maps and real-time tracking tools to anticipate potential bottlenecks and adjust workflows accordingly. The result is a more resilient system that can adapt to varying site conditions without sacrificing quality or safety standards.

Beyond immediate benefits, streamlined processes contribute significantly to the overall sustainability of solar initiatives. By reducing waste and minimizing disruptions to local environments, these methods support greener practices. This not only enhances the project's reputation but also fosters community acceptance, paving the way for a smoother transition to renewable energy sources in diverse regions.

Expert Engineering Support and Quality Assurance in Clamp Manufacturing

In the world of clamp manufacturing, expert engineering support is the backbone of a successful operation. Our team of seasoned engineers works closely with clients from the initial design phase through to production, ensuring that every clamp is tailored to meet specific industrial needs. We leverage advanced CAD software and simulation tools to optimize designs for strength, durability, and efficiency, all while keeping an eye on cost-effectiveness and ease of use. This hands-on approach helps prevent costly errors down the line and guarantees that the final product performs flawlessly under real-world conditions.

Quality assurance in clamp manufacturing isn't just a checkpoint; it's a continuous commitment to precision and reliability. We implement rigorous testing protocols, including tensile strength tests, fatigue analysis, and material inspections, to verify that each clamp can withstand the stresses of its intended application. Our quality control processes are integrated throughout the manufacturing cycle, from raw material sourcing to final assembly, allowing us to catch potential issues early and maintain consistency across batches. This dedication to quality ensures that our clamps not only meet but often exceed industry standards and customer expectations.

What truly sets us apart is the seamless integration of engineering support and quality assurance into a cohesive strategy. By fostering collaboration between our design and production teams, we create a feedback loop that enhances innovation and problem-solving. Whether it's developing custom clamps for specialized machinery or refining standard products for enhanced performance, this synergy allows us to deliver solutions that are robust, reliable, and ready for any challenge. In an industry where safety and durability are paramount, our commitment to these principles ensures that every clamp we produce stands the test of time.

Sustainable Clamping Solutions Contributing to Eco-Friendly Solar Energy Systems

Innovative clamping solutions are transforming solar installations by using recycled plastics and rust-resistant metals, which reduce environmental impact without sacrificing durability. These components ensure panels remain secure in harsh weather, enhancing the system's overall longevity and reliability.

By optimizing the design to fit various panel types, these clamps minimize on-site waste during installation, making the process quicker and more efficient. This approach not only cuts down labor costs but also aligns with sustainable practices by reducing material use and promoting modular setups that are easy to upgrade over time.

In the long run, eco-friendly clamps play a crucial role in extending the lifespan of solar arrays, which boosts energy output and lowers the carbon footprint. Their adaptability supports the transition to greener energy systems, contributing significantly to a cleaner, more sustainable future.

FAQ

Our clamps feature a unique corrosion-resistant alloy that withstands harsh weather conditions, ensuring longevity without compromising on ease of installation. Unlike standard models, they include integrated rubber padding to prevent panel damage and reduce vibration noise.

They are designed with a quick-lock mechanism that allows installers to secure panels in under 30 seconds each, significantly cutting down labor time. The lightweight yet durable construction also reduces handling fatigue on larger solar arrays.

Yes, our clamping system is versatile and fits most panel thicknesses from 30mm to 50mm, including monocrystalline, polycrystalline, and thin-film varieties. Adjustable brackets are available for custom installations if needed.

We use aerospace-grade aluminum with a powder-coated finish for enhanced durability against UV exposure and moisture. This material choice ensures a balance of strength and weight, making them ideal for both residential and commercial setups.

Absolutely. They are tested to support up to 5400 Pa snow loads and wind speeds exceeding 150 mph, meeting international standards for safety. The design includes reinforced locking points to prevent slippage under stress.

We prioritize eco-friendly practices by using recycled materials in production and minimizing waste. Our clamps are also fully recyclable at the end of their lifecycle, aligning with the green energy goals of solar installations.

Conclusion

As a leading manufacturer in the solar panel clamping industry, this company specializes in high-quality clamping solutions that enhance the efficiency and reliability of solar installations. By integrating innovative clamping technologies, they significantly improve solar panel durability, ensuring that panels withstand harsh environmental conditions without compromising performance. Their customized clamp designs cater to a wide range of installation requirements, whether on residential rooftops or large-scale commercial sites, offering tailored solutions that fit seamlessly into diverse solar projects. This flexibility, combined with the use of durable materials and corrosion-resistant finishes, guarantees long-term performance and minimal maintenance needs, contributing to overall cost-effectiveness.

Furthermore, the company prioritizes streamlined installation processes that boost efficiency on solar projects, reducing labor time and complexity while maintaining high safety standards. Expert engineering support and rigorous quality assurance are integral to their manufacturing process, ensuring that each clamp meets stringent industry standards and performs reliably in the field. Additionally, their commitment to sustainable clamping solutions aligns with eco-friendly solar energy systems, promoting environmental responsibility throughout the product lifecycle. By focusing on these key aspects, they deliver clamping solutions that not only enhance installation efficiency but also support the broader goal of advancing renewable energy adoption through robust and reliable components.

Contact Us

Contact Person: Nancy

Email: [email protected]

Tel/WhatsApp: +86-13365923720

Website: https://www.topfencesolar.com/